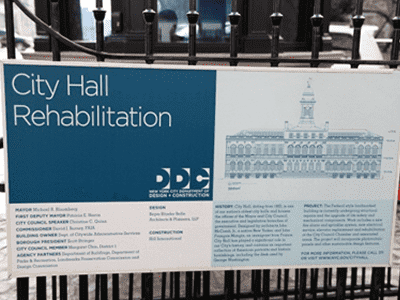

Multi-phase Stabilization of an Icon: The Longest Continuously Operating City Hall in the United States

Location: New York, NY

Age/Built: 1810-1812

Crack Repair, Gruenstark (GS) Anchors, Services, Stabilization of Historic Structures, Testing and Analysis

Project Background:

- New York City Hall is listed on the National Register of Historic Places and is a National Historic Landmark

- One of the most recognizable government buildings in America, the Hall has been the subject of several films, TV shows, and musical efforts

- As part of a multi-phase $119 million rehabilitation program, Masonry Solutions was contracted to repair and stabilize a variety of critical areas

Challenges Presented:

- Due to foundation movement caused by construction of a nearby subway line, differential settlement had damaged brick and stone masonry

- Cracking throughout the interior masonry walls, arches and vaults, most critically in the historic rotunda

- The grand fireplace exhibited signs of severe cracking

- The marble rotunda stairs contained void patterns and open joints, compromising continuity and load transfer

- Prior repair attempts had resulted in further damage

- No aesthetics could be altered and no operations disrupted

Services and Solutions:

- MSI technicians used a variety of NDE techniques, including ground penetrating radar, ultrasonic pulse velocity, and video scoping to determine structural composition and develop protocols

- The deepest analysis was needed for the historic rotunda

- Masonry Solutions drilled with care and precision to allow for their stainless steel Gruenstark (GS) fabric anchors, which were securely fastened the sections of masonry to resist further cracking

- MSI technicians applied a two stage CIF injection protocol on the interior stone walls and arches, first targeting small internal voids and then using a micro-fine injection within cracked areas

- A separate custom CIF mix was used to bond sets of anchors with the surrounding substrate, stabilizing the structure while CIF injection at the foundations took place to prevent future movement

- The marble rotunda stairs were injected with another custom mix, one that matched not only characteristics like vapor transmission and compressive strength, but also matched aesthetic characteristics like color and finish

- Stair injection took place in joints as small as 3/32”

- NDE confirmed all project goals were met, with the stair injection showing a healthy 6ft of travel between ports

- Constant effort was given so that the government’s operations were undisturbed and the aesthetics of this famous construction remained unchanged