Stabilizing and Retrofitting New Orleans' Critical Pumping Stations to Withstand High Wind and Flood

Location: New Orleans, LA

Age/Built: 1908

Crack Repair, Gruenstark (GS) Anchors, Services, Stabilization of Historic Structures, Testing and Analysis, Wind and Flood Enhancement

Project Background:

- Hurricane Katrina struck New Orleans in 2005

- It was the costliest natural disaster in US history (over $81 billion in damages) and the deadliest since 1928

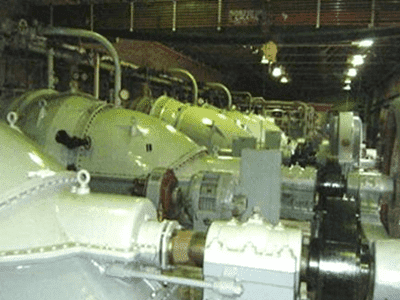

- New Orleans, built in a basin below sea level, relies on a series of pumping installations to keep from flooding

- Many of these stations are over 100 years old and were at risk should another significant hurricane strike

Challenges Presented:

- The Army Corps of Engineers was given a mandate to retrofit their pump stations to withstand a category 3 hurricane, which can have sustained winds over 130 mph

- Due to their historic nature, several stations required special attention so as to stabilize their historic fabric

- Masonry Solutions International was contracted across a number of these multi-million dollar projects and was asked to perform the critical task of structurally enhancing the aging installations

- MSI worked with a wide variety of contractors during their efforts, adding a host of complex logistical and communicative challenges

Services and Solutions:

- Masonry Solutions began by non-destructively evaluating the various installations, one of which contained a complex of buildings, using techniques such as microwave radar

- In-situ testing included ASTM C1197 and ASTM C1072

- Utilizing this battery of tests, MSI laboratory engineers then developed a compatible injection fill (CIF) for each station, calibrating their material properties to the characteristics of any intended host. One historic station alone received over 840,000 lbs. of CIF

- Next, Masonry Solutions injection team developed a low pressure injection protocol that accounted for the historic nature of the stations as well their void structures

- Prior to injection, a vast series of enhancement rods were needed, with over 50,000 linear ft. of Gruenstark stainless steel fabric anchorage furnished and installed by MSI

- This anchorage represented the highest level of security possible, employing MSI’s undercut geometric locking design, allowing higher than typical loads to be withstood

- To place this anchorage, Masonry Solutions applied advanced long-bore dry coring techniques, at times coring over 160 ft. for one anchor

- Masonry Solutions performed their work with the utmost care for the continuing operations of these important historic yet functional installations

- All stations’ appearances were maintained and no service interruptions were experienced

- This work represents the largest CIF and masonry anchorage effort in US history to date