Stablization and Seismic Retrofit for an Historic Religious Institution

Location: Charleston, SC

Age/Built: 1848

Seismic Retrofit, Services, Stabilization of Historic Structures, Testing and Analysis

Project Background:

- Founded in 1846, Grace Episcopal Church in South Carolina is a towering building with a fascinating history

- During the civil war, suffered damage from considerable federal shelling. While other churches closed during the war, Grace remained open

- In 1886, a seismic event known as the Great Charleston Earthquake, caused massive amounts of destruction in the area

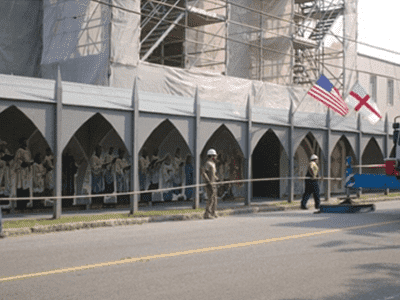

- A multi-million dollar campaign dubbed “Saving Grace”, was created over 160 years after the Great Charleston Earthquake to correct lingering structural problems

Challenges Presented:

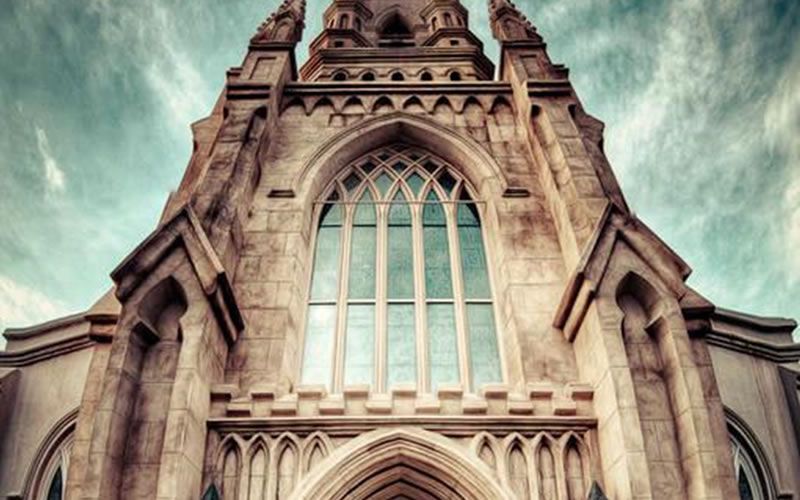

- It was discovered several features had deteriorated and become unsafe due to damage sustained in 1886

- The tower had begun to lean toward the church, and pressure from the tower combined with weak mortar caused the vertical layers of brick to separate

- Smaller area earthquakes had affect the building further

- MSI was contracted to assess the church’s structural condition and help introduce a seismic retrofit program

Services and Solutions:

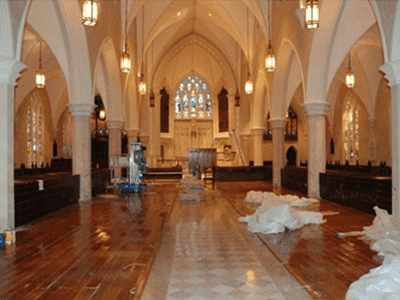

- Masonry Solutions International began by working with design professionals to supply a non-linear dynamic analysis of the steeple tower

- Using evaluative techniques such as flatjack testing, anchor shear and tension testing, petrographic analysis, MSI laboratory engineers developed a comprehensive report on the church’s condition

- Utilizing MSI’s expertise and input, the design team crafted a comprehensive structural reinforcement plan

- Building upon this vision, MSI’s staff developed protocols to achieve the objectives set forth by the design team

- MSI techs carefully cored the entire length and height of the steeple walls, utilizing advanced precision dry coring, cautious to not damage the already fragile structure

- Masonry Solutions then installed a series of hollow injectable Gruenstark multi-wythe stainless steel reinforcements, which would be used as applicators for CIF injection

- Next, using a custom formulated CIF material designed to match the church’s historic properties, MSI techs injected the walls of the tower to solidify them and mobilize their stainless steel reinforcements

- Finally, NDE provided confirmation that the objectives were achieved and that MSI’s work was a success

- The repairs were tested when an earthquake struck the church shortly after project activity concluded. Small electronic monitors installed by the design team verified the tower did not move during the event