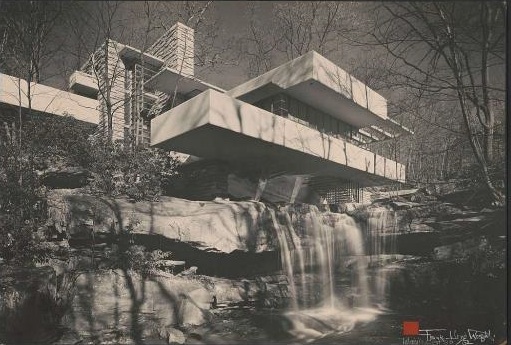

Defending a World Renown Masterpiece of American Architecture

Location: Mill Run, PA

Age/Built: 1936-1939

CIF injection, Custom Solutions, Facade Repair and Attachment, Foundation settlement, Gruenstark (GS) Anchors, Historic Stabilization, Long-bore Dry Coring, Moisture Prevention, NDE, Stabilization of Historic Structures, Testing and Analysis, Wind and Flood Enhancement

Project Background:

- Voted the "best all-time work of American architecture" and "building of the century", Fallingwater is one of a few buildings in the US on the UNESCO World Heritage List.

- Designed in 1935 by American architect Frank Lloyd Wright (1867-1959), the main house was constructed 1936-38, followed by the guest house in 1939.

- Since Fallingwater opened in 1964, over 6 million visitors from around the world have toured the house.

Challenges Presented:

- Since its construction several areas at the main and guest house were experiencing severe leaking, cause major concerns for ownership and stewards of the icon.

- Much of the existing interior finishes and furniture, which themselves are historic and major hallmarks of the tour, would need to remain in place during injection and ultimately needed moisture infiltration to stop.

- The masonry underlying the cantilevered covered bridge section was also in danger due to the potential for rotation and a lack of adequate internal reinforcing.

Services and Solutions:

- As a 3-year delegated design project, MSI and its team began by evaluating the venerated structure to determine what steps were necessary for intervention.

- The evaluation used fiber-optic borescopes and ground penetrating radar to evaluate any underlying structural conditions and various avenues for moisture infiltration.

- MSI worked with the whole project team and building stakeholders to develop an appropriate methodology, one that helped solidify the masonry at Fallingwater and protect its many critical architectural details.

- Masonry Solutions developed a customized, compatible CIF, one that would maintain the proper level of breathability and improve moisture resistance.

- MSI technicians, utilizing a specialized low pressure injection system, including tight fitting 3D printed nozzles, installed CIF within the masonry with the utmost consideration, eliminating leaks, limiting movement and ensuring long-term structural stability.

- Complicating matters a natural spring running into the building could not be negatively impacted during work, requiring techs to avoid filling certain internal pathways despite extremely fluid material being necessary.

- Further MSI designed, manufactured, and installed custom injectable anchorage that was both non-corrosive and non-epoxy based, stabilizing the cantilevered section of masonry at the covered walkway.

- This momentous effort paid off and was met with great acclaim. MSI was even mentioned by name in a major Wall Street Journal article about the work.