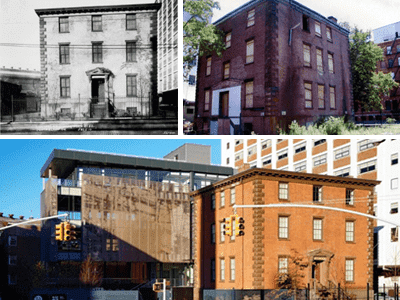

Preserving a Piece of Naval History for an Ambitious LEED Project

Location: Brooklyn, NY

Age/Built: 1855-1857

Adaptive Reuse, Custom Solutions, Facade Repair and Attachment, LEED Projects, Services, Stabilization of Historic Structures, Testing and Analysis

Project Background:

- Building 92 is located on the grounds of the Brooklyn Navy Yard, one of the first five naval shipyards, developed into the nation’s premiere industrial facility

- It was designed by Thomas U. Walter, who also designed the US Capitol Building’s central dome

- Today the Navy Yard is home to the highest concentration of manufacturing and green business in New York City

Challenges Presented:

- As part of a $16.5 million LEED project, the owners of building 92 wanted to convert the aging structure into a new museum complex and visitor center

- The historic four story building would be joined by a striking 23,500 sq. ft. glass extension

- To achieve this bold vision, and gain a Platinum LEED designation, the project team aimed to preserve the original 150 year old building in its entirety

- The masonry shell was in very bad condition, with project members expressing concerns over a possible collapse, particularly with 3 of the facades

Services and Solutions:

- Masonry Solutions began by evaluating the masonry shell to determine a safe method of rehabilitation, utilizing NDE to uncover detailed information on its underlying structural condition

- Masonry Solutions laboratory engineers developed a compatible injection material that was sympathetic to the host’s particular characteristics

- MSI technicians utilized a low pressure CIF injection protocol and filled the cavities between the layers of bricks forming the exterior walls

- Injection presented a number of challenges, including the creation of an isolation barrier that would keep injection material from flowing into non-prescribed areas

- MSI technicians used a series of custom stainless steel installations in conjunction with a unique applicator to create this shelf, successfully isolating the intended injection area

- CIF Injection took place from the building interior and all ports were constructed between the walls’ very thin mortar joints, both aspects requiring the utmost precision and care

- Further NDE confirmed all objectives were achieved, the facades were stabilized, and the project team was free to pursue their ambitious goals

- Building 92 was awarded with a coveted Platinum LEED designation shortly after the conclusion of project activities